By Kirt Zimmer, Head of Social Media Marketing, Marvell

The OFC 2025 event in San Francisco was so vast that it would be easy to miss a few stellar demos from your favorite optical networking companies. That’s why we took the time to create videos featuring the latest Marvell technology.

Put them all together and you have a wonderful film festival for technophiles. Enjoy!

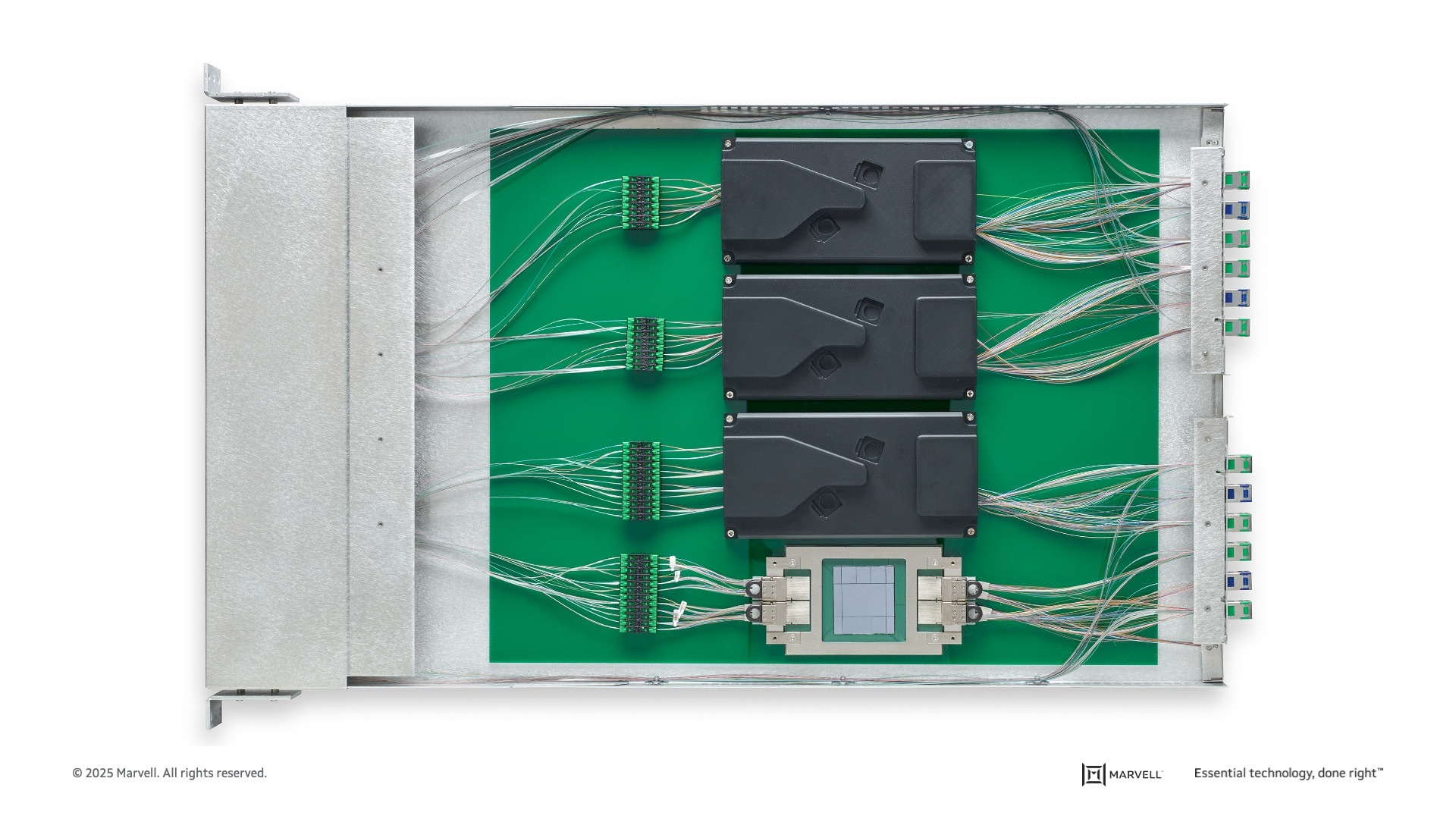

We spoke with Kishore Atreya, Senior Director of Cloud Platform Marketing at Marvell, who discussed co-packaged optics. Instead of moving data via electrons, a light engine converts electrical signals into photons—unlocking ultra-high-speed, low-power optical data transfer.

The 1.6T and 6.4T light engines from Marvell can be integrated directly into the chip package, minimizing trace lengths, reducing power and enabling true plug-and-play fiber connectivity. It is flexible, scalable, and built for switching, XPUs, and beyond.

By Nizar Rida, Vice President of Engineering and Country Manager, Marvell Canada

This blog first appeared in The Future Economy

AI has the potential to transform the way we live. But for AI to become sustainable and pervasive, we also have to transform our computing infrastructure.

The world’s existing technologies, simply put, weren’t designed for the data-intensive, highly parallel computing problems that AI serves up. As a result, AI clusters and data centers aren’t nearly as efficient or elegant as they could be: in many ways, it’s brute force computing. Power1 and water2 consumption in data centers are growing dramatically and many communities around the world are pushing back on plans to expand data infrastructure.3

Canada can and will play a leading role in overcoming these hurdles. Data center expansion is already underway. Data centers currently account for around 1GW, or 1%, of Canada’s electricity capacity. If all of the projects in review today get approved, that total could grow to 15GW, or enough to power 70% of the homes in the country.4

Like in other regions, data center operators are exploring ways to increase their use of renewables and nuclear in these new facilities along with ambient cooling to reduce their carbon footprint of their facilities. In Alberta, some companies are also exploring adding carbon capture to the design of data centers powered by natural gas. To date, carbon capture has not lived up to its promise.5 Most carbon capture experiments, however, have been coupled with large-scale industrial plants. It may be worth examining if carbon capture—combined with mineralization for long-term storage—can work on this smaller scale. If it does, the technology could be exported to other regions.

Fixing facilities, however, is only part of the equation. AI requires a fundamental overhaul in the systems and components that make up our networks.

Above: The server of the future. The four AI processors connect to networks through four 6.4T light engines, the four smaller chips on the east-west side of the exposed processor. Coupling optical technology with the processor lowers power per bit while increasing bandwidth.

By Michael Kanellos, Head of Influencer Relations, Marvell

You’re likely assaulted daily with some zany and unverifiable AI factoid. By 2027, 93% of AI systems will be able to pass the bar, but limit their practice to simple slip and fall cases! Next-generation training models will consume more energy than all Panera outlets combined! etc. etc.

What can you trust? The stats below. Scouring the internet (and leaning heavily on 16 years of employment in the energy industry) I’ve compiled a list of somewhat credible and relevant stats that provide perspective to the energy challenge.

1. First, the Concerning News: Data Center Demand Could Nearly Triple in a Few Years

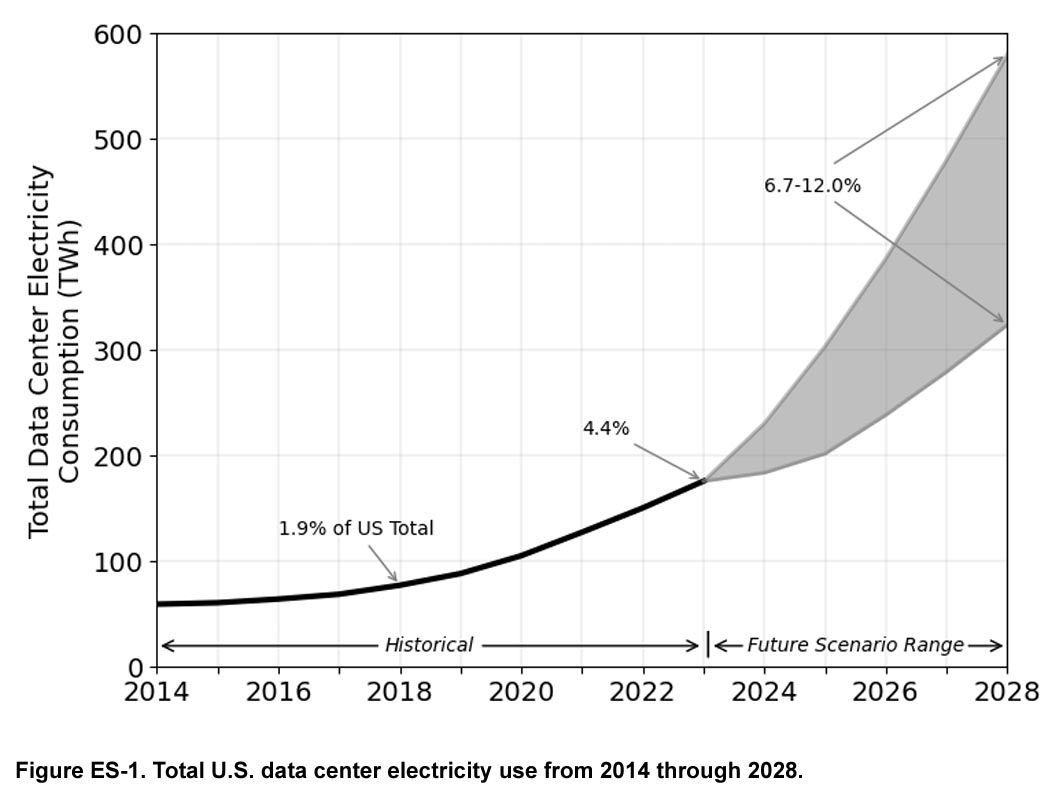

Lawrence Livermore National Lab and the Department of Energy1 has issued its latest data center power report and it’s ominous.

Data center power consumption rose from a stable 60-76 terawatt hours (TWh) per year in the U.S. through 2018 to 176 TWh in 2023, or from 1.9% of total power consumption to 4.4%. By 2028, AI could push it to 6.7%-12%. (Lighting consumes 15%2.)

Report co-author Eric Masanet adds that the total doesn’t include bitcoin, which increases 2023’s consumption by 70 TWh. Add a similar 30-40% to subsequent years too if you want.

This article was originally published in VentureBeat.

Artificial intelligence is about to face some serious growing pains.

Demand for AI services is exploding globally. Unfortunately, so is the challenge of delivering those services in an economical and sustainable manner. AI power demand is forecast to grow by 44.7% annually, a surge that will double data center power consumption to 857 terawatt hours in 20281: as a nation today, that would make data centers the sixth largest consumer of electricity, right behind Japan’s2 consumption. It’s an imbalance that threatens the “smaller, cheaper, faster” mantra that has driven every major trend in technology for the last 50 years.

It also doesn’t have to happen. Custom silicon—unique silicon optimized for specific use cases—is already demonstrating how we can continue to increase performance while cutting power even as Moore’s Law fades into history. Custom may account for 25% of AI accelerators (XPUs) by 20283 and that’s just one category of chips going custom.

The Data Infrastructure is the Computer

Jensen Huang’s vision for AI factories is apt. These coming AI data centers will churn at an unrelenting pace 24/7. And, like manufacturing facilities, their ultimate success or failure for service providers will be determined by operational excellence, the two-word phrase that rules manufacturing. Are we consuming more, or less, energy per token than our competitor? Why is mean time to failure rising? What’s the current operational equipment effectiveness (OEE)? In oil and chemicals, the end products sold to customers are indistinguishable commodities. Where they differ is in process design, leveraging distinct combinations of technologies to squeeze out marginal gains.

The same will occur in AI. Cloud operators already are engaged in differentiating their backbone facilities. Some have adopted optical switching to reduce energy and latency. Others have been more aggressive at developing their own custom CPUs. In 2010, the main difference between a million-square-foot hyperscale data center and a data center inside a regional office was size. Both were built around the same core storage devices, servers and switches. Going forward, diversity will rule, and the operators with the lowest cost, least downtime and ability to roll out new differentiating services and applications will become the favorite of businesses and consumers.

The best infrastructure, in short, will win.

The Custom Concept

And the chief way to differentiate infrastructure will be through custom infrastructure that are enabled by custom semiconductors, i.e., chips containing unique IP or features for achieving leapfrog performance for an application. It’s a spectrum ranging from AI accelerators built around distinct, singular design to a merchant chip containing additional custom IP, cores and firmware to optimize it for a particular software environment. While the focus is now primarily on higher value chips such as AI accelerators, every chip will get customized: Meta, for example, recently unveiled a custom NIC, a relatively unsung chip that connects servers to networks, to reduce the impact of downtime.

By Ravindranath C Kanakarajan, Senior Principal Engineer, Switch BU

Marvell has been actively involved with SONiC since its beginning, with many SONiC switches powered by Marvell® ASICs at hyperscalers deployed worldwide. One of Marvell's goal has been to enhance SONiC to address common issues and optimize its performance for large-scale deployments.

The Challenge

Many hackathon projects have focused on improving the monitoring, troubleshooting, debuggability, and testing of SONiC. However, we believe one of the core roles of a network operating system (NOS) is to optimize the use of the hardware data plane (i.e., the NPUs and networking ASICs). As workloads become increasingly more demanding, it becomes crucial to maximize the efficiency of the data plane. Commercial black-box NOS are tailored to specific NPUs/ASICs to achieve optimal performance. SONiC, however, supports a diverse range of NPUs/ASICs, presenting a unique challenge.

We at Marvell have been contributing features to SONiC to ensure optimal use of the underlying networking ASIC resources. Over time, we’ve recognized the need to provide operators with flexibility in utilizing ASIC resources while reducing the platform-specific complexity gradually being introduced into SONiC’s core component, the Orchagent. This approach will help SONiC operators to maintain consistent device configurations even when using devices from different platform vendors.

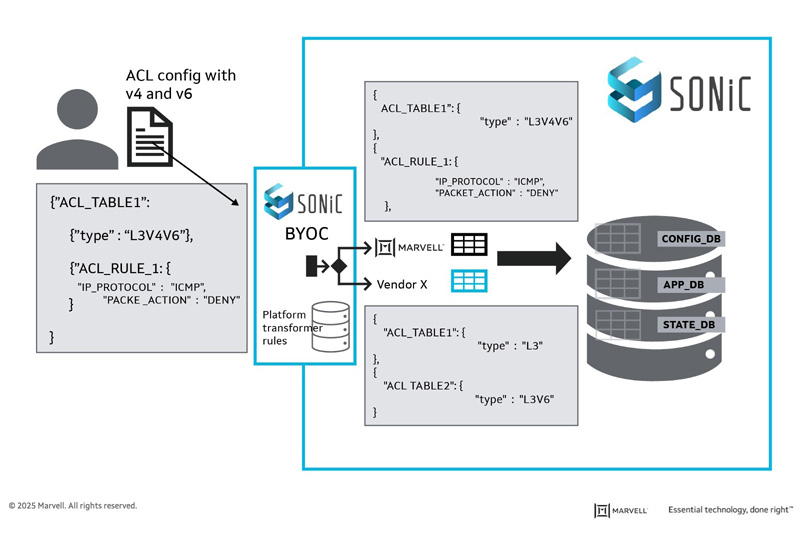

BYOC

During the Hackathon, we developed a framework called “BYOC: Bring Your Own Configuration,” allowing networking ASIC vendors to expose their hardware capabilities in a file describing intent. A new agent transforms the user’s configuration into an optimal SONiC configuration based on the capabilities file. This approach allows ASIC vendors to ensure that user configurations are converted to optimal ASIC configurations. It also allows SONiC operators to fine-tune the hardware resources consumed based on the deployment needs. It further helps in optimally migrating configurations from vendor NOS to SONiC based on the SONiC platform’s capability.