- 製品

- 会社概要

- サポート

- 製品

- タイプ別

- 市場別

コンピューティング

ネットワーキング

ストレージ

カスタム

- 会社概要

The USR-Alliance – Enabling an Open Multi-Chip Module (MCM) Ecosystem

The semiconductor industry is witnessing exponential growth and rapid changes to its bandwidth requirements, as well as increasing design complexity, emergence of new processes and integration of multi-disciplinary technologies. All this is happening against a backdrop of shorter development cycles and fierce competition. Other technology-driven industry sectors, such as software and hardware, are addressing similar challenges by creating open alliances and open standards. This blog does not attempt to list all the open alliances that now exist -- the Open Compute Project, Open Data Path and the Linux Foundation are just a few of the most prominent examples. One technological area that still hasn’t embraced such open collaboration is Multi-Chip-Module (MCM), where multiple semiconductor dies are packaged together, thereby creating a combined system in a single package.

The semiconductor industry is witnessing exponential growth and rapid changes to its bandwidth requirements, as well as increasing design complexity, emergence of new processes and integration of multi-disciplinary technologies. All this is happening against a backdrop of shorter development cycles and fierce competition. Other technology-driven industry sectors, such as software and hardware, are addressing similar challenges by creating open alliances and open standards. This blog does not attempt to list all the open alliances that now exist -- the Open Compute Project, Open Data Path and the Linux Foundation are just a few of the most prominent examples. One technological area that still hasn’t embraced such open collaboration is Multi-Chip-Module (MCM), where multiple semiconductor dies are packaged together, thereby creating a combined system in a single package.

The MCM concept has been around for a while, generating multiple technological and market benefits, including:

- Improved yield - Instead of creating large monolithic dies with low yield and higher cost (which sometimes cannot even be fabricated), splitting the silicon into multiple die can significantly improve the yield of each building block and the combined solution. Better yield consequently translates into reductions in costs.

- Optimized process - The final MCM product is a mix-and-match of units in different fabrication processes which enables optimizing of the process selection for specific IP blocks with similar characteristics.

- Multiple fabrication plants - Different fabs, each with its own unique capabilities, can be utilized to create a given product.

- Product variety - New products are easily created by combining different numbers and types of devices to form innovative and cost‑optimized MCMs.

- Short product cycle time - Dies can be upgraded independently, which promotes ease in the addition of new product capabilities and/or the ability to correct any issues within a given die. For example, integrating a new type of I/O interface can be achieved without having to re-spin other parts of the solution that are stable and don’t require any change (thus avoiding waste of time and money).

- Economy of scale - Each die can be reused in multiple applications and products, increasing its volume and yield as well as the overall return on the initial investment made in its development.

Sub-dividing large semiconductor devices and mounting them on an MCM has now become the new printed circuit board (PCB) - providing smaller footprint, lower power, higher performance and expanded functionality.

Now, imagine that the benefits listed above are not confined to a single chip vendor, but instead are shared across the industry as a whole. By opening and standardizing the interface between dies, it is possible to introduce a true open platform, wherein design teams in different companies, each specializing in different technological areas, are able to create a variety of new products beyond the scope of any single company in isolation.

This is where the USR Alliance comes into action. The alliance has defined an Ultra Short Reach (USR) link, optimized for communication across the very short distances between the components contained in a single package. This link provides high bandwidth with less power and smaller die size than existing very short reach (VSR) PHYs which cross package boundaries and connectors and need to deal with challenges that simply don’t exist inside a package. The USR PHY is based on a multi-wire differential signaling technique optimized for MCM environments.

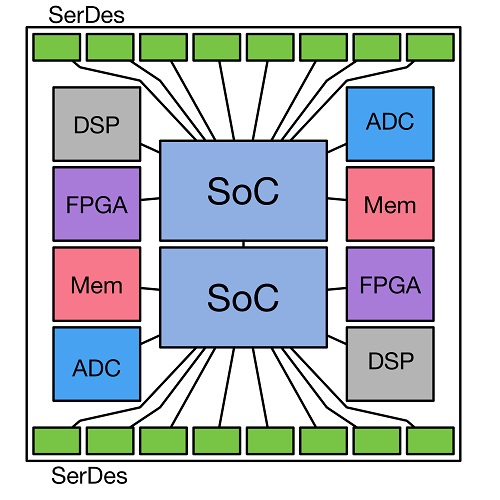

There are many applications in which the USR link can be implemented. Examples include CPUs, switches and routers, FPGAs, DSPs, analog components and a variety of long reach electrical and optical interfaces.  図 1:Example of a possible MCM layout

図 1:Example of a possible MCM layout

Marvell is an active promoter member of the USR Alliance and is working to create an ecosystem of interoperable components, interconnects, protocols and software that will help the semiconductor industry bring more value to the market. The alliance is working on creating PHY, MAC and software standards and interoperability agreements in collaboration with the industry and other standards development organizations, and is promoting the development of a full ecosystem around USR applications (including certification programs) to ensure widespread interoperability.

To learn more about the USR Alliance visit: www.usr-alliance.org

最新の記事

- HashiCorp and Marvell: Teaming Up for Multi-Cloud Security Management

- Cryptomathic and Marvell: Enhancing Crypto Agility for the Cloud

- The Big, Hidden Problem with Encryption and How to Solve It

- Self-Destructing Encryption Keys and Static and Dynamic Entropy in One Chip

- Dual Use IP: Shortening Government Development Cycles from Two Years to Six Months

アーカイブス

カテゴリ

- 5G (12)

- AI (11)

- 車載機器 (26)

- クラウド (7)

- コヒーレントDSP (2)

- 企業ニュース(100)

- カスタムシリコンソリューション (1)

- データセンター (39)

- データ処理ユニット (22)

- エンタープライズ (25)

- ESG (6)

- イーサネット・アダプター、コントローラー (12)

- イーサネット PHY (4)

- イーサネットスイッチ (30)

- ファイバーチャネル (10)

- Marvell Government Solutions (2)

- ネットワーク (31)

- Optical Modules (9)

- セキュリティ (3)

- Server Connectivity (15)

- SSD コントローラ (6)

- ストレージ (22)

- ストレージの推進者 (2)

- What Makes Marvell (21)

- Coherent DSP (3)

- 企業ニュース(3)

- Optical Module (3)

- PAM4 DSP (3)

- セキュリティ (3)

会社情報

リクルーティング情報

表示言語 (Language)

Copyright © 2024 Marvell, All Rights Reserved

- 利用規約

- プライバシーポリシー

- お問い合わせ先