Archive for the 'Ethernet PHYs' Category

-

February 10, 2023

マーベルのデータセンター・インターコネクト・ソリューションが2023年ライトウェーブ・イノベーション賞を受賞

By Kristin Hehir, Senior Manager, PR and Marketing, Marvell

Marvell has been honored with two 2023 Lightwave Innovation Reviews high scores, validating its leadership in PAM4 DSP solutions for data infrastructure. The two awards reflect the industry’s recognition of Marvell’s recent best-in-class innovations to address the growing bandwidth and interconnect needs of cloud data center networks. An esteemed and experienced panel of third-party judges from the optical communications community recognized Marvell as a high-scoring honoree.

“On behalf of the Lightwave Innovation Reviews, I would like to congratulate Marvell on their high-scoring honoree status,” said Lightwave Editorial Director, Stephen Hardy. “This competitive program allows Lightwave to celebrate and recognize the most innovative products impacting the optical communications community this year.”

Marvell was recognized for the Marvell® Alaska® A PAM4 DSP Family for Active Electrical Cables (AECs) and the Marvell® Spica™ Gen 2 800G PAM4 Electro-Optics Platform, both in the Data Center Interconnect Platforms category. Key features of these 2023 Lightwave Innovation Reviews honorees include:

-

November 08, 2022

TSNとプレステラDX1500: ITとOTの溝を越える架け橋

By Reza Eltejaein, Director, Product Marketing, Marvell

Manufacturers, power utilities and other industrial companies stand to gain the most in digital transformation. Manufacturing and construction industries account for 37 percent of total energy used globally*, for instance, more than any other sector. By fine-tuning operations with AI, some manufacturers can reduce carbon emission by up to 20 percent and save millions of dollars in the process.

Industry, however, remains relatively un-digitized and gaps often exist between operational technology – the robots, furnaces and other equipment on factory floors—and the servers and storage systems that make up a company’s IT footprint. Without that linkage, organizations can’t take advantage of Industrial Internet of Things (IIoT) technologies, also referred to as Industry 4.0. Of the 232.6 million pieces of fixed industrial equipment installed in 2020, only 10 percent were IIoT-enabled.

Why the gap? IT often hasn’t been good enough. Plants operate on exacting specifications. Engineers and plant managers need a “live” picture of operations with continual updates on temperature, pressure, power consumption and other variables from hundreds, if not thousands, of devices. Dropped, corrupted or mis-transmitted data can lead to unanticipated downtime—a $50 billion year problem—as well as injuries, blackouts, and even explosions.

To date, getting around these problems has required industrial applications to build around proprietary standards and/or complex component sets. These systems work—and work well—but they are largely cut off from the digital transformation unfolding outside the factory walls.

The new Prestera® DX1500 switch family is aimed squarely at bridging this divide, with Marvell extending its modern borderless enterprise offering into industrial applications. Based on the IEEE 802.1AS-2020 standard for Time-Sensitive Networking (TSN), Prestera DX1500 combines the performance requirements of industry with the economies of scale and pace of innovation of standards-based Ethernet technology. Additionally, we integrated the CPU and the switch—and in some models the PHY—into a single chip to dramatically reduce power, board space and design complexity.

Done right, TSN will lower the CapEx and OpEx for industrial technology, open the door to integrating Industry 4.0 practices and simplify the process of bringing new equipment to market. -

2018年1月10日

Moving the World’s Data

マーベル、PR チーム

The way in which data is moved via wireline and wireless connectivity is going through major transformations. The dynamics that are causing these changes are being seen across a broad cross section of different sectors.

Within our cars, the new features and functionality that are being incorporated mean that the traditional CAN and LIN based communication technology is no longer adequate. More advanced in-vehicle networking needs to be implemented which is capable of supporting multi-Gigabit data rates, in order to cope with the large quantities of data that high resolution cameras, more sophisticated infotainment, automotive radar and LiDAR will produce. With CAN, LIN and other automotive networking technologies not offering viable upgrade paths, it is clear that Ethernet will be the basis of future in-vehicle network infrastructure - offering the headroom needed as automobile design progresses towards the long term goal of fully autonomous vehicles. Marvell is already proving itself to be ahead of the game here, following the announcement of the industry’s first secure automotive gigabit Ethernet switch, which delivers the speeds now being required by today’s data-heavy automotive designs, while also ensuring secure operation is maintained and the threat of hacking or denial of service (DoS) attacks is mitigated.

Within the context of modern factories and processing facilities, the arrival of Industry 4.0 will allow greater levels of automation, through use of machine-to-machine (M2M) communication. This communication can enable the access of data — data that is provided by a multitude of different sensor nodes distributed throughout the site. The ongoing in-depth analysis of this data is designed to ultimately bring improvements in efficiency and productivity for the modern factory environment. Ethernet capable of supporting Gigabit data rates has shown itself to be the prime candidate and it is already experiencing extensive implementation. Not only will this meet the speed and bandwidth requirements needed, but it also has the robustness that is mandatory in such settings (dealing with high temperatures, ESD strikes, exposure to vibrations, etc.) and the low latency characteristics that are essential for real-time control/analysis. Marvell has developed highly sophisticated Gigabit Ethernet transceivers with elevated performance that are targeted at such applications.

Within data centers things are changing too, but in this case the criteria involved are somewhat different. Here it is more about how to deal with the large volumes of data involved, while keeping the associated capital and operational expenses in check. Marvell has been championing a more cost effective and streamlined approach through its Prestera® PX Passive Intelligent Port Extender (PIPE) products. These present data center engineers with a modular approach to deploy network infrastructure that meets their specific requirements, rather than having to add further layers of complexity unnecessarily that will only serve to raise the cost and the power consumption. The result is a fully scalable, more economical and energy efficient solution.

ワイヤレス領域では、家庭、オフィス、自治体、小売店などの環境において、WLANハードウェアに対するプレッシャーがますます大きくなっている。 ネットワーク事業者やサービスプロバイダーは、ユーザー密度の増加や全体的なデータ容量の増加だけでなく、ユーザーの行動にも現在起きている変化に対応する必要がある。 Wi-Fi接続は、もはやデータをダウンロードするためだけのものではなく、データのアップロードがますます重要な考慮事項となるだろう。 これは、拡張リアリティゲーム、HDビデオコンテンツの共有、クラウドベースの創作活動など、さまざまな用途に必要とされる。 これに対処するため、Wi-Fi技術は、アップリンクとダウンリンクの帯域幅能力を向上させる必要がある。

The introduction of the much anticipated 802.11ax protocol is set to radically change how Wi-Fi is implemented. Not only will this allow far greater user densities to be supported (thereby meeting the coverage demands of places where large numbers of people are in need of Internet access, such as airports, sports stadia and concert venues), it also offers greater uplink/downlink data capacity - supporting multi-Gigabit operation in both directions. Marvell is looking to drive things forward via its portfolio of recently unveiled multi-Gigabit 802.11ax Wi-Fi system-on-chips (SoCs), which are the first in the industry to have orthogonal frequency-division multiple access (OFDMA) and multi-user MIMO operation on both the downlink and the uplink.

Check out www.marvell.com to learn more about how Marvell is moving the world’s data.

Check out www.marvell.com to learn more about how Marvell is moving the world’s data. -

November 06, 2017

The USR-Alliance – Enabling an Open Multi-Chip Module (MCM) Ecosystem

By Gidi Navon, Senior Principal Architect, Marvell

The semiconductor industry is witnessing exponential growth and rapid changes to its bandwidth requirements, as well as increasing design complexity, emergence of new processes and integration of multi-disciplinary technologies. All this is happening against a backdrop of shorter development cycles and fierce competition. Other technology-driven industry sectors, such as software and hardware, are addressing similar challenges by creating open alliances and open standards. This blog does not attempt to list all the open alliances that now exist -- the Open Compute Project, Open Data Path and the Linux Foundation are just a few of the most prominent examples. One technological area that still hasn’t embraced such open collaboration is Multi-Chip-Module (MCM), where multiple semiconductor dies are packaged together, thereby creating a combined system in a single package.

The semiconductor industry is witnessing exponential growth and rapid changes to its bandwidth requirements, as well as increasing design complexity, emergence of new processes and integration of multi-disciplinary technologies. All this is happening against a backdrop of shorter development cycles and fierce competition. Other technology-driven industry sectors, such as software and hardware, are addressing similar challenges by creating open alliances and open standards. This blog does not attempt to list all the open alliances that now exist -- the Open Compute Project, Open Data Path and the Linux Foundation are just a few of the most prominent examples. One technological area that still hasn’t embraced such open collaboration is Multi-Chip-Module (MCM), where multiple semiconductor dies are packaged together, thereby creating a combined system in a single package. The MCM concept has been around for a while, generating multiple technological and market benefits, including:

- Improved yield - Instead of creating large monolithic dies with low yield and higher cost (which sometimes cannot even be fabricated), splitting the silicon into multiple die can significantly improve the yield of each building block and the combined solution. Better yield consequently translates into reductions in costs.

- Optimized process - The final MCM product is a mix-and-match of units in different fabrication processes which enables optimizing of the process selection for specific IP blocks with similar characteristics.

- Multiple fabrication plants - Different fabs, each with its own unique capabilities, can be utilized to create a given product.

- Product variety - New products are easily created by combining different numbers and types of devices to form innovative and cost‑optimized MCMs.

- Short product cycle time - Dies can be upgraded independently, which promotes ease in the addition of new product capabilities and/or the ability to correct any issues within a given die. For example, integrating a new type of I/O interface can be achieved without having to re-spin other parts of the solution that are stable and don’t require any change (thus avoiding waste of time and money).

- Economy of scale - Each die can be reused in multiple applications and products, increasing its volume and yield as well as the overall return on the initial investment made in its development.

Sub-dividing large semiconductor devices and mounting them on an MCM has now become the new printed circuit board (PCB) - providing smaller footprint, lower power, higher performance and expanded functionality.

Now, imagine that the benefits listed above are not confined to a single chip vendor, but instead are shared across the industry as a whole. By opening and standardizing the interface between dies, it is possible to introduce a true open platform, wherein design teams in different companies, each specializing in different technological areas, are able to create a variety of new products beyond the scope of any single company in isolation.

This is where the USR Alliance comes into action. The alliance has defined an Ultra Short Reach (USR) link, optimized for communication across the very short distances between the components contained in a single package. This link provides high bandwidth with less power and smaller die size than existing very short reach (VSR) PHYs which cross package boundaries and connectors and need to deal with challenges that simply don’t exist inside a package. The USR PHY is based on a multi-wire differential signaling technique optimized for MCM environments.

There are many applications in which the USR link can be implemented. Examples include CPUs, switches and routers, FPGAs, DSPs, analog components and a variety of long reach electrical and optical interfaces.

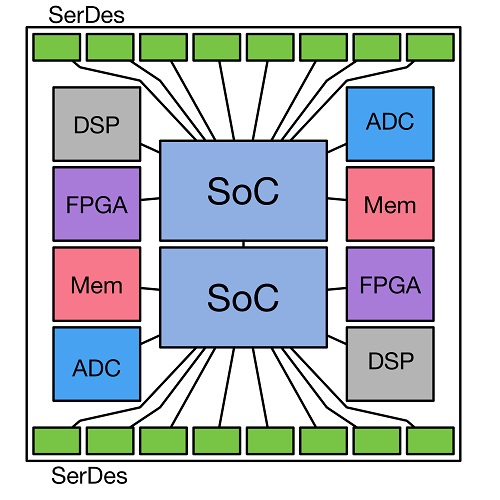

図 1:Example of a possible MCM layout

図 1:Example of a possible MCM layout Marvell is an active promoter member of the USR Alliance and is working to create an ecosystem of interoperable components, interconnects, protocols and software that will help the semiconductor industry bring more value to the market. The alliance is working on creating PHY, MAC and software standards and interoperability agreements in collaboration with the industry and other standards development organizations, and is promoting the development of a full ecosystem around USR applications (including certification programs) to ensure widespread interoperability.

To learn more about the USR Alliance visit: www.usr-alliance.org

最新の記事

- HashiCorp and Marvell: Teaming Up for Multi-Cloud Security Management

- Cryptomathic and Marvell: Enhancing Crypto Agility for the Cloud

- The Big, Hidden Problem with Encryption and How to Solve It

- Self-Destructing Encryption Keys and Static and Dynamic Entropy in One Chip

- Dual Use IP: Shortening Government Development Cycles from Two Years to Six Months